During the past decade, warehouses, distribution centers (DCs) and manufacturing facilities have begun to take giant leaps toward increasingly implementing autonomous material handling technology.

While autonomous technologies vary — from infrastructure-heavy embedded wires or tape to help steer automated guided vehicles (AGVs), to LiDAR (light detection and ranging) to vision-guided tuggers and forklifts, the goals essentially remain the same: reduce dependence on human labor and improve workplace safety.

Beyond AGVs in the warehouse, there may realistically come a day when yard trucks themselves may very well become their own form of autonomous vehicles.

The need then arises concerning how such autonomous technology will communicate with the dock. How will such vehicles know and understand when to approach and leave the dock? And in the not too distant future, how would an autonomous forklift know when to enter a trailer to start unloading or loading pallets in a pre-configured pattern?

Making it easy to automate operations

A perfect complement to such technology is digitally-driven, modeled-object technology at the dock that will connect with the growing use of autonomous vehicles and communicate with that technology to make it easier to automate warehouse and DC operations.

The easier and simpler the integration with third-party equipment means that facilities won’t have to create their own proprietary closed systems that can result in a host of potential problems to ensure they work correctly.

Today’s answer to the ever-evolving future of dock operation is to ensure that the data at the dock is accessible to any third-party (AGV, etc.) autonomous equipment. It needs to communicate and perform as a whole rather than via 13 separate parts.

Warning: Undefined variable $media_modals in /app/wordpress/wp-content/themes/kelley2017/section-media.php on line 63

It then also pays to ask yourself how you expect to see the data generated and how you expect to get that data? Or have you even thought about such questions in the first place?

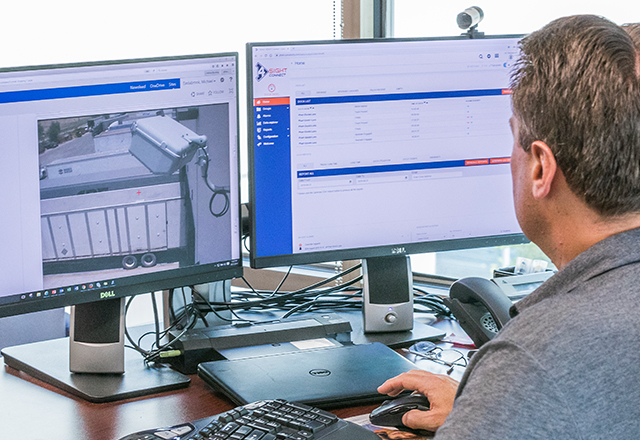

Through the use of a digital master control panel, including a graphic-driven human machine interface (HMI) and strategically-placed QR codes, the dock is able to easily communicate and interface with a facility’s autonomous technology concerning the status of the dock, current safety status of equipment as well as key management or supervisory personnel. All of that communication between the dock and autonomous equipment becomes part of one big data structure.

In fact, in such an environment, the digital master control panel itself becomes the cornerstone of a much larger system as technology grows and evolves. In addition, the control panel increases transparency with a vast number of items within the warehouse or DC.

How digitally-connected dock equipment communicates

It’s important to understand that the digitally-driven dock equipment does not communicate directly with the autonomous vehicles themselves. The digital master control panel’s HMI and PLC first communicate into the cloud, feed all of the data to a specially-designed central platform and expose everything as API calls.

An AGV, for example, would then be able to determine through an exchange of information when it’s safe to enter a trailer. It needs to know that the restraint is engaged properly, that the dock leveler is seated on the trailer floor and that the dock door is open and secure as well. Once all of the equipment on the dock is in its proper position, then the AGV knows it’s safe to enter a trailer at will.

Should anything change during that time, such as a restraint becoming undone or dock door malfunctioning, the system will communicate the changes in status and send an alert for appropriate action.

These types of actions will even help to protect equipment by sending it the appropriate data so that an expensive autonomous forklift doesn’t accidentally wander beyond a door opening and fall crashing into the yard where an unrestrained trailer once stood.

If you’d like to learn more about integrating your dock with evolving autonomous material handling technology, Kelley is uniquely prepared to help you because we’re carefully watching the future right along with you.